What Is Laser Engraving | A Comprehensive Guide

Laser engraving, simply put, is a process where a laser engraving machine is used to focus a beam of light to etch designs, patterns, or text onto various materials' surfaces. You can think of laser engraving as also vaporizing the surface of certain materials when it's laser beam hits a certain temperature.

Over my laser engraving journey, I've used many different methods of laser engraving, each tailored to suit different materials, from wood and metal to glass and plastics.

In this article, I'll be sharing insights into the art and science of laser engraving, covering its technology, applications, advantages, and much more. Join me as we find out the amazing world of laser engraving together.

Laser engraving, simply put, is a process where a laser engraving machine is used to focus a beam of light to etch designs, patterns, or text onto various materials' surfaces. Over my laser engraving journey, I've used many different methods of laser engraving, each tailored to suit different materials, from wood and metal to glass and plastics.

In this article, I'll be sharing insights into the art and science of laser engraving, covering its technology, applications, advantages, and much more. Join me as we find out the amazing world of laser engraving together.

Types of lasers used in engraving

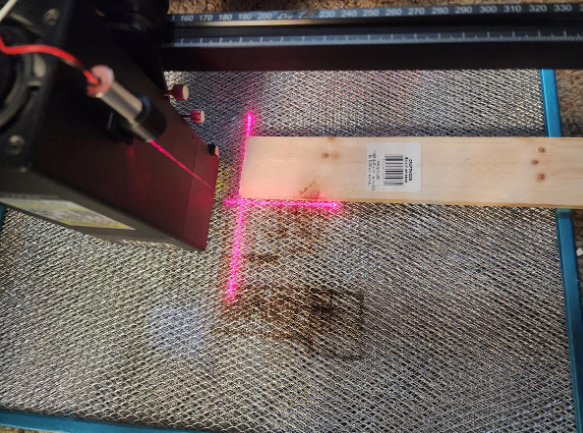

In my year of laser engraving experience, I've come to appreciate the diversity of lasers available for this hobby I'm in. Each has its unique strengths and applications and also weaknesses. On my YouTube channel at engravingthat.com, I've shared my experience with my 20W diode laser and hopefully soon I'll be sharing my experience with the other popular types of laser engravers.

- One of the most common lasers is the CO2 laser. These lasers are versatile and excel at engraving organic materials like wood, leather, and paper. Their ability to produce high-quality engravings with intricate details makes them a favorite among hobbyists and professionals like myself.

- Another type of laser engraver is the fiber laser. These lasers are ideal for engraving metals like stainless steel, aluminum, and brass. With their high powered laser beam, fiber lasers create crisp markings and deep engravings on different materials. This makes them indispensable for industrial applications and personalized metal products. This is the type of laser I want to work with next.

- Next up are diode lasers, known for their affordability and compact size. While not as powerful as CO2 or fiber lasers, diode lasers are perfect for engraving on smaller surfaces like jewelry or electronics. These can also be used to cut wood and leather-like materials. I have many examples of the items and project you can complete with one of these.

Each type of laser brings its own set of advantages and disadvantages. But, through trial and error, you can learned to leverage their capabilities to achieve stunning results in your engraving projects.

Whether it's CO2, fiber, or diode lasers, the key is understanding their strengths and limitations. When you know what they are, you will be able to unlock their full potential in creating unique and visually appealing engravings.

Materials suitable for laser engraving

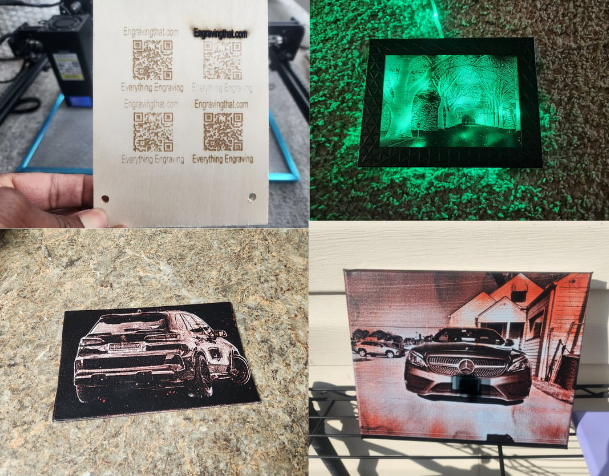

When it comes to laser engraving, the choice of materials plays an important role in the outcome of my projects. Over my year of experience, I've found myself drawn to working with wood more than any other material. There's something inherently satisfying about the way wood reacts to laser engraving, producing rich contrasts and intricate details that really stand out.

One of my favorite types of wood to work with is hardwood, such as maple, cherry, or walnut. I can usually find some form of these types of wood in stores like Walmart Or Dollar Tree. These types of woods gives beautiful, deep engravings with amazing clarity. This makes them perfect for decorative items, signage, and personalized gifts. I love engraving cutting boards as Christmas gifts. You're able to personalized something for a family member that they will almost use on a daily basis.

Softwoods like pine and cedar are also excellent choices for laser engraving, albeit with slightly different results. Their softer nature allows for faster engraving speeds and smoother finishes, making them ideal for larger projects or mass production.

Aside from wood, I've also experimented with other materials that are work good with laser engraving. Acrylic, for instance, offers a sleek and modern look, but takes more prep-work than wood to actually work. Metals like stainless steel and aluminum are perfect for personalized jewelry, keychains, and industrial applications.

Plastics, leather, glass, and even stone are among the myriad of materials I've explored in my laser engraving hobby. Each material presents its own set of challenges and opportunities, and part of the joy of laser engraving is discovering the unique characteristics of each.

- Wood (hardwood and softwood)

- Acrylic

- Leather

- Paper and cardboard

- Glass

- Metal (stainless steel, aluminum, brass)

- Plastics (such as ABS, PVC, and acrylic)

- Stone (like marble, granite, and slate)

- Ceramic

- Fabric (cotton, denim, polyester)

Showcase of successful laser engraving projects

These are some of the projects that I have completed with the 20 Watt laser. Some of these were accomplished from a first try on my laser engraver. I have come a long way since I started about a year ago.

Safety measures for operating laser engraving machines

One thing I can't stress enough is the need to take safety very seriously when working with laser engravers. These machines emit a laser beam that can cause serious harm if proper precautions aren't taken.

Here are some essential safety measures for operating laser engraving machines:

- Wear appropriate laser safety glasses to protect your eyes from the laser beam. Most machines come with one as a part of the kit. My laser engraver included one and I ensure that I wear it at all times.

- Ensure proper ventilation to remove smoke, fumes, and particulates from your workspace.

- Keep a fire extinguisher nearby just incase there are any flames. Some of the materials that you will be laser engraving will be flammable. Some of these materials include: wood, cardboard, and paper.

- Regularly inspect and maintain your machine according to the manufacturer's guidelines. Not following the maintenance schedule can lead to a machine with a short lifespan.

- You never want to trip over anything so keep the work area clean and organized to minimize accidents.

- Only allow qualified individuals to handle the machine. Inexperience can lead to very bad accidents. An inexperienced person might not know they should wear protective glasses while operating a laser engraver.

Temperature where some metals vaporize

Different metals' surface vaporize at different temperatures. Below is a list of different metals and the temperature their surface vaporize at.

- Aluminum: 2327°C

- Copper: 2595°C

- Iron: 3000°C

- Lead: 1750°C

- Magnesium: 1110°C

- Zinc: 906°C

What about melting point of different types of metals?

- Aluminum 6061: 585°C

- Aluminum 380: 566°C

- Carbon Steel: 1425—1540°C

- Lead: 327.5°C

- Magnesium: 650°C

- Stainless Steel Grade 304: 1400—1450°C

- Stainless Steel Grade 316: 1375—1400°C

Should You Get A Laser Engraver?

The question sometimes arise whether or not you should get a laser engraver or not. I did not think about getting a laser engraver until

Conclusion

It's amazing to look back at all I've learned in just a year of laser engraving. Who knew a laser beam could be such a versatile tool? I've gone from simply understanding the basics to experimenting with different techniques and materials, and I'm excited to see what the future holds.

This journey has been about so much more than just the mechanics. It's about the satisfaction of creating something unique and beautiful, and about the challenge of pushing the boundaries of what I thought was not possible. There's a real sense of accomplishment in taking a piece of raw material and transforming it into something special.

Please feel free to reach out to me with all the different creations you have made on your laser engraving journey. I will gladly post your work on my blog.

Related Articles

-

How to Laser Engrave Leather | Step-By-Step Guide

Can You Laser Engrave Leather?

How to Laser Engrave White Tiles Painted Black?

What Is The Best Low Cost Laser Engraver? My Opinion

How to Laser Engrave Acrylic with a Diode Laser: A Step-by-Step Guide

My Hands-On Review of the Monport 6-Watt Diode Laser Engraver

Laser Etching Glass

Laser Engraving A Photo | Full Guide

How Much Does Laser Engraving Cost

Is Laser Engraving Hard to Learn?

Why is laser engraving so expensive?

WHAT IS A LASER CUTTING MACHINE?

Top 7 Laser Engraving Business Ideas

10 Essential Safety Precautions for Home Laser Engraving Projects

Laser Engraving Cutting Boards | How To

Where To Buy Laser Cutting Materials?

Laser Engraving QR Codes

What Is DPI In Laser Engraving

How Much Is A Laser Engraving Machine