Laser Engraving Aluminum | All You Need To Know

Laser engravers are able to engrave aluminum in different ways. You will be able to accomplish awesome designs using either a diode, fiber, or CO2 laser. I have been using my diode laser to create many engravings and markings on different aluminum items.

My favorite is making dog tags for friends and family. Below I will be going over everything you need to know in order to accomplish great looking engravings on aluminum pieces.

How Does Engraving Aluminum Work?

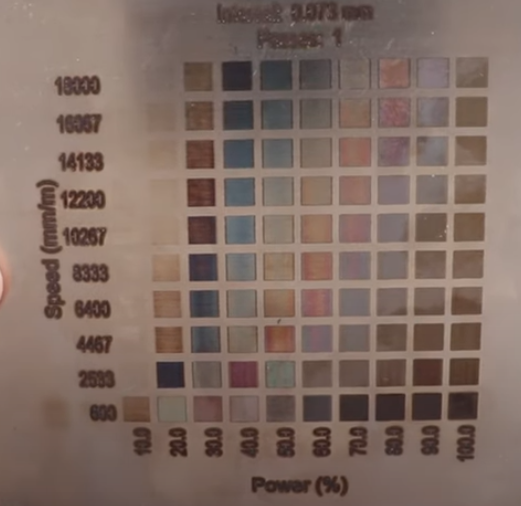

Engraving aluminum is an awesome thing to witness. But please, always wear your safety glasses if you ever decide to see what is happening while engraving. The laser engraver fires a beam of light on the surface of aluminum at different temperatures which in turn creates different colors. Below is an image of the results you can get depending on the type of laser you have.

Credit: CSLdesigns

As you can see in the test above, running you laser engraver at different speeds and power settings will decide which type of color is created on the surface of your piece of aluminum. Looking at the image you can see that in order to get somewhat of a dark blue color, you would need to run this laser engraver at a power setting of 40% and a speed of 16057mm/m.

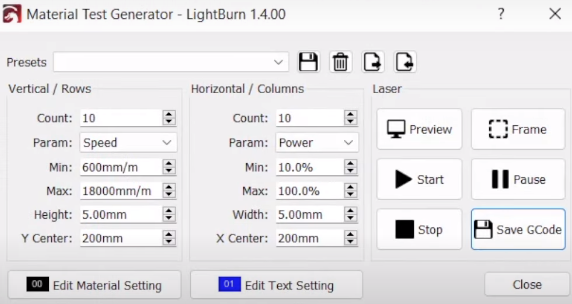

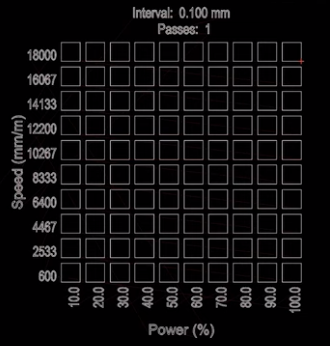

Test like these are necessary for working with laser engravers. One of the best tool for setting this up is offered by Lightburn. It is called Materials Test and will be shown below.

You are able to set the amount of columns and rows you want in the test. If you choose the default which is 10 columns and 10 rows, you will get an output like the one below.

The more columns and more rows you choose to use in your test the more options you will be able to choose from.

What Kind of Laser Do You Need?

Each laser engraver offer different levels of power levels and capabilities. The cheapest laser engraver you can purchase will usually be a diode laser. If you have more money to spend, you can opt for a fiber laser or CO2 laser engraver.

Now let's move on to the best laser engraver for your needs.

1. CO2 Laser Engraver

A CO2 laser engraver is able to engrave anodized aluminum, bare aluminum, and powder-coated aluminum. The only real downside to purchasing one of these is the upfront cost. You can expect to pay upwards of $5000 for a good quality unit. There is one CO2 laser on amazon called the Monport 40W 2.0 Laser Engraver (8" X 12") for around $550. However, as you can see from the name, it only comes with a working area of 8 inches by 12 inches. That means you will not be able to engrave anything large. Remember, the average printer paper is 8 inches by 11 inches.

2. Diode Laser Engraver

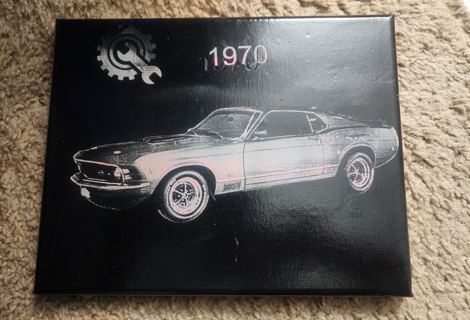

These types of lasers are the most popular among beginners and hobbyists. I currently own one of these and I have been enjoying creating many gifts and trinkets for family and friends. Most of the engraving images on this blog were created with my diode laser engraver. I might as well go ahead and show you guys one more of my creations below.

The laser engraver I chose to go with was the Longer Ray5 20W diode laser. I paid $582 for it in December of 2023.

If you do choose to use a diode laser engraver, you will be limited to engraving only powder-coated aluminum and also anodized aluminum. You will not be be able to engrave bare aluminum like you would with a CO2 laser engraver.

3. Fiber Laser Engraver

This laser engraver is very expensive and will usually only be used by small to large businesses. This is however one of the best lasers for aluminum as you can engrave bare, anodized, or even powder-coated aluminum without any prep-work . The reason why this laser is third on this list is that it isn't suited for other types of materials like non-metals.

You can expect to pay upwards of $7000 if you want a good one. You can get one on amazon.

Conclusion

The best laser engraver for aluminum will all depend on the use case you have in mind. If you have the budget and will opnly be doing metals, then a fiber laser will be perfect. However, if you will be doing other types of materials you will want to get a CO2 or diode laser. But please keep in mind that each laser have their own advantages and disadvantages.

Related Articles

-

How to Laser Engrave Leather | Step-By-Step Guide

Can You Laser Engrave Leather?

How to Laser Engrave White Tiles Painted Black?

What Is The Best Low Cost Laser Engraver? My Opinion

How to Laser Engrave Acrylic with a Diode Laser: A Step-by-Step Guide

My Hands-On Review of the Monport 6-Watt Diode Laser Engraver

Laser Etching Glass

Laser Engraving A Photo | Full Guide

How Much Does Laser Engraving Cost

Is Laser Engraving Hard to Learn?

Why is laser engraving so expensive?

WHAT IS A LASER CUTTING MACHINE?

Top 7 Laser Engraving Business Ideas

10 Essential Safety Precautions for Home Laser Engraving Projects

Laser Engraving Cutting Boards | How To

Where To Buy Laser Cutting Materials?

Laser Engraving QR Codes

What Is DPI In Laser Engraving

How Much Is A Laser Engraving Machine