Is Laser Engraving Hard to Learn?

Is Laser Engraving Hard to Learn?

When I first got into laser engraving, I’ll admit that I was a little overwhelmed. I wasn’t sure how steep the learning curve would be. As it turns out, it's not as intimidating as I thought, but there are definitely a few things to keep in mind. I will go over all the different obstacles I went through.

What is laser engraving?

Laser engraving is the process of using a laser engraver to focus a beam of light on a surface to remove some of the said surface.

So, is laser engraving hard to learn?

Well, it depends on a few things. Here are some questions to consider:

- Are you comfortable with technology?

Laser engraving involves working with software to design and prepare your image or text before it gets engraved. If you’ve used graphic design programs before, you’ll probably feel more at ease. But if you’re completely new to it, expect a bit of a learning curve. Here are some of these software: Lightburn, LaserGRBL, EZCAD, CorelDRAW, Adobe Illustrator.

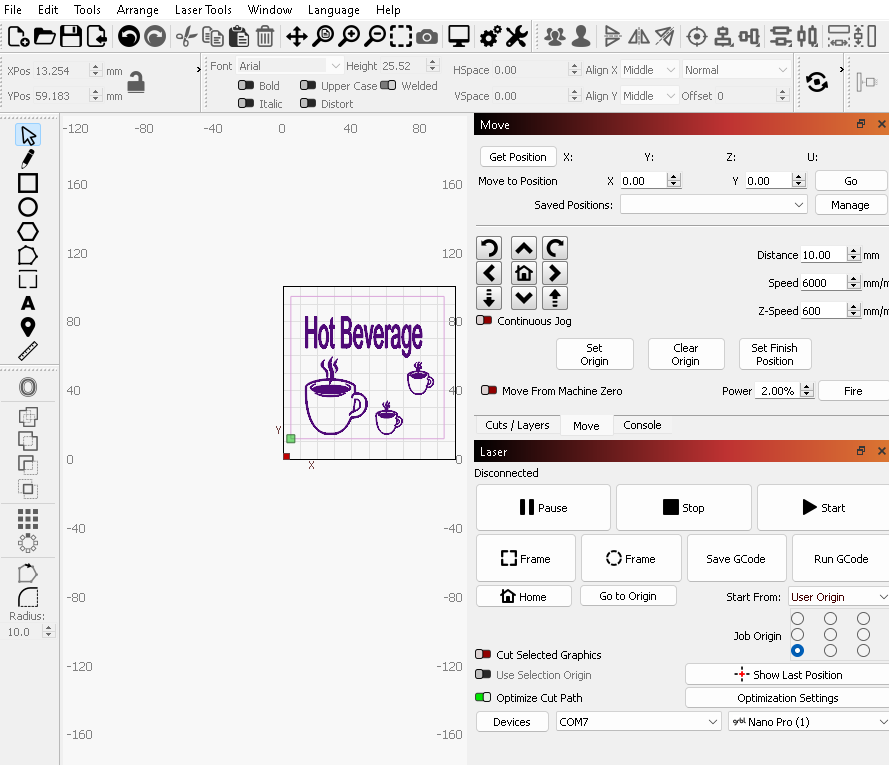

Some laser engraving software can be intimidating with all the buttons and options. Look at the screenshot below and let me if there's a lot going on.

- Do you have the patience to learn from mistakes?

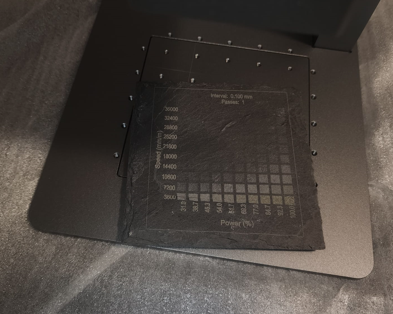

Laser engraving can be as much about trial and error as it is about creativity. Sometimes you’ll burn through a piece of fabric or over-engrave a piece of metal because you misjudged the alignment. This has been remedied with some software that allow you do run tests on the piece of material you will be using. One such software is Lightburn that offers a materials test option in its settings. Here is a screenshot of that a material test done on slate.

- What kind of material do you plan to engrave?

Some materials are more forgiving than others. This is why prior research is necessary. Wood, for example, is a bit easier to get started with than metal or glass, which can be tricky. The type of machine you choose to invest in will also define the types of materials you can laser engrave successfully. For instance, you wouldn't choose a diode laser to engrave on copper over a fiber laser.

CO2 Laser Engraver:

- Wood

- Glass

- Acrylic

- Leather

- Paper

- Fabrics

- Rubber

- Ceramics

- Plastics (certain types)

- Anodized aluminum

- Marble

- Stone

Fiber Laser Engraver:

- Stainless steel

- Aluminum

- Brass

- Copper

- Titanium

- Tungsten

- Chrome

- Nickel

- Gold

- Silver

- Platinum

- Certain plastics (e.g., ABS, polycarbonate)

Diode Laser Engraver:

- Wood

- Paper

- Leather

- Certain plastics (e.g., ABS, acrylic)

- Cardboard

- Fabric

If you see any mistakes, please feel free to let me know.

My Experience: The First Few Days

When I first got my laser engraver, I really couldn't wait to get started. But before I even received it, I was constantly watching Youtube videos on how to set it up and how to start the first engraving. I had a ton of ideas in my head, and I have to say that I do have a knack for anything that involves technology.

If I remember correctly, the first thing I engraved was a dog paw print on a piece of wood which turned out great. This was mainly because the settings and pawprint were sent along with the laser engraver. Here is a picture of that engraving.

Here's what really helped me was breaking the learning process into smaller steps:

- Start simple: Focus on basic shapes and text before jumping into complex designs like a full photograph.

- Learn your machine: Play around with settings like speed and power. This is where the test material option in Lightburn helped me out a lot.

- Experiment with materials: Don’t just stick to one type of material. Experimenting with wood, metal, and acrylic will teach you how each one reacts differently to your laser. This will also show you the limits of the machine you currently own.

Types of laser engravers and their ease of learning

There are a few main types of laser engravers, each with different learning curves:

-

Diode Laser Engravers

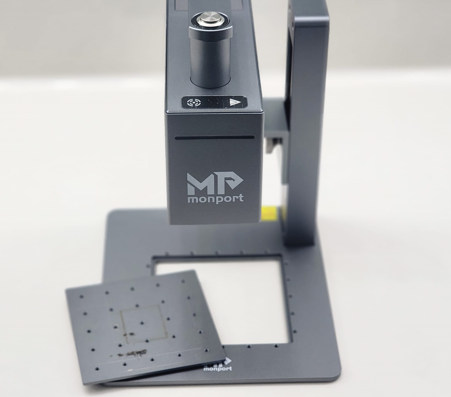

These types of lasers are great for beginners as they have a small learning curve and are usually affordable and user-friendly. These are perfect for hobbyists like myself. They work well on wood and some anodized metals, but have limited power for other materials like aluminum, brass, gold or acrylic. I currently own the Longer Ray 5 20 watt diode laser engraver which has been awesome. I just invested in another diode laser which is the Monport 6W Diode Laser.

-

Fiber Laser Engravers

This machine is a bit more advanced, mainly used for metals like stainless steel or aluminum. While these are more powerful, they can be tricky to learn, especially when it comes to adjusting settings for different metals. Again, this is where the material test comes into play.

-

CO2 Laser Engravers

These are ok for beginners! These are versatile and work well on wood, acrylic, leather, and more. These are usually more expensive than diode lasers.

What to Expect as You Learn

Software Learning Curve: Whether you’re using LaserGRBL, Lightburn, or any other software, this is probably where you’ll spend the most time learning. It's always wise to experiment with different types of materials to know which ones you're more comfortable with and to also know which ones your machine can handle easily.

- Material Sensitivity: Not all wood engraves the same, and metals react very differently depending on their composition. All materials react differently to different temperatures and this more true when dealing with a laser. A laser engraver emits plenty of heat unto the surface of the material being

- Fine-Tuning: Every project you take on will require adjustments to power, speed, and focus. Getting the hang of this can feel tedious at first, but soon enough, it becomes second nature.

So, What’s the Verdict?

Is laser engraving hard to learn? Yes and no. If you’re expecting to master it in a day, you’ll probably be frustrated. But if you enjoy learning and are willing to be patient with yourself, it’s an incredibly rewarding skill to pick up. Every project teaches you something new, and before you know it, you’ll be able to take on more complex designs without a second thought.

If you’re still on the fence, ask yourself these questions:

- Do I enjoy hands-on learning?

- Am I comfortable with technology, or at least willing to get comfortable?

- Am I prepared to make a few mistakes along the way?

- Is it worth buying a laser engraving machine?

- What is the best laser engraver for beginners?

If you can answer “yes” to any these, I’d say go for it. If not, then maybe this isn't the type of activity you want to get involved in.

When it comes to laser engraving, the range of materials you can work with is pretty impressive. You can engrave on:

- Wood: Perfect for signs, gifts, and artwork.

- Acrylic: Great for creating sleek, modern designs with a glossy finish.

- Metal: Ideal for durable, professional-looking engravings, like custom tools or plaques using materials like copper or stainless steel.

- Glass: Perfect for personalized drinkware or awards.

- Leather: Adds a custom touch to wallets, belts, or journals.

- Cardboard: You can cut cardboards into different shapes to create special gift boxes. You can also

- Printed Circuit Board:

How much money can a laser engraver make?

The income from laser engraving can vary widely based on the products you sell, your pricing, and the demand in your niche market. If you target a specific niche like personalized gifts or signage, you could scale monthly earnings to anywhere from $1,000 to over $10,000. Profit margins typically range from 30% to 60% depending on the purchase price of the raw materials like canvas or pieces of wood.

What is the difference between laser etching and laser engraving?

The main difference lies in depth and material removal. Laser engraving involves physically removing material to create deeper cuts, while laser etching is more surface-level and alters the material's surface properties rather than cutting into it.

What type of laser is best for engraving?

CO2 lasers are versatile and widely used for engraving non-metal materials like wood, leather, and acrylic. Fiber lasers are ideal for engraving metals, and diode lasers are good for smaller, budget-friendly projects.

Each has its advantages, but for general engraving, CO2 is often the go-to option.

Related Articles

-

How to Laser Engrave Leather | Step-By-Step Guide

Can You Laser Engrave Leather?

How to Laser Engrave White Tiles Painted Black?

What Is The Best Low Cost Laser Engraver? My Opinion

How to Laser Engrave Acrylic with a Diode Laser: A Step-by-Step Guide

My Hands-On Review of the Monport 6-Watt Diode Laser Engraver

Laser Etching Glass

Laser Engraving A Photo | Full Guide

How Much Does Laser Engraving Cost

Is Laser Engraving Hard to Learn?

Why is laser engraving so expensive?

WHAT IS A LASER CUTTING MACHINE?

Top 7 Laser Engraving Business Ideas

10 Essential Safety Precautions for Home Laser Engraving Projects

Laser Engraving Cutting Boards | How To

Where To Buy Laser Cutting Materials?

Laser Engraving QR Codes

What Is DPI In Laser Engraving

How Much Is A Laser Engraving Machine