6 Steps on How to Laser Engrave Metal

How Does Laser Engraving Metal Work?

It can be very hard to laser engrave metal. There are many things to take into consideration like the laser engraver type and the type of metal you will be engraving. Engraving metal can be straightforward as long as you know what you are doing and have the right engraver for the job.

How to Laser Engrave Metal?

Laser engraving metal is not hard as long as you have the right laser engraver for the job.

1. Choose the right laser engraver

A fiber laser should be chosen for this job. They are however usually on the pricey side. You can find some good ones in the $1500 range such as the Gweike G2 Laser Engraver.

2. Prepare Your Work Area

This is necessary as you will be dealing with fumes and tiny metal particles that comes from laser engraving metals. If inhaled, this can cause damage to your health. You have to ensure that there is proper ventilation to remove fumes created during engraving. You will also want to do the following:

- Wear appropriate safety gear. These include items such as laser safety glasses and gloves.

- Clean and degrease the metal surface for optimal engraving results.

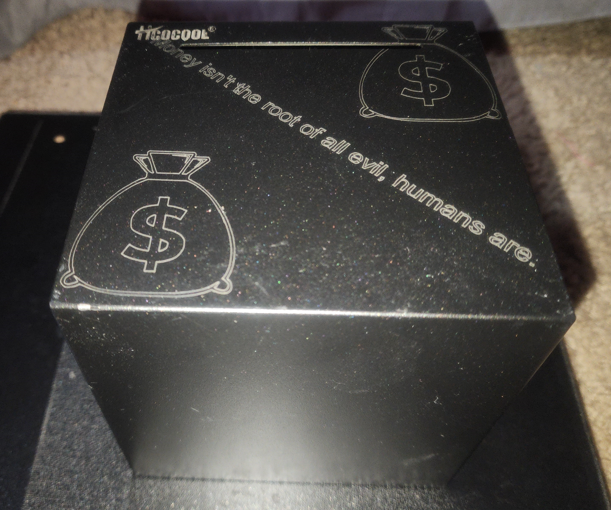

3. Design and Import Your Artwork

This section usually include using software such as Lightburn or gimp to design your artwork. Whether it be of a simple business card or a simple worded logo. You will want to ensure you design your image or text on a compatible software program for your specific machine. I have gotten used to using lightburn and love it as there are many people online that can help you out whenever you don't know something or you're stuck getting bad engravings. There are usually people out there that experienced what you are experiencing and can give you tips on how ton solve it.

Make sure the design you choose to create is in a format accepted by your laser's control software. Some lasers do not support Lightburn and other popular laser engraving software.

4. Set Laser Parameters

One thing us men never like to do is read the manual that comes with different products. We usually don't read the manual until we get stuck somehow. But when it comes to laser engraving, it's always best to read all manuals. It is recommended that you read your machine's manual or manufacturer recommendations for starting points.

These manuals usually give you typical parameters for metal engraving with a fiber laser. These can be in adjusting the power, scan speed, and frequency. You will want to start with conservative settings and test on scrap metal to fine-tune for desired depth and detail.

Testing on scrap is one of the best tips I can ever give you.

5. Position Material and Focus Laser

This step is important as you do not want your material moving around while being engraved. You want to secure the metal piece firmly in the laser's working area. Most metal engravers come equipped with fasteners for you to use.

The next thing you need to do is to focus the machine to achieve a sharp and clean laser beam on the metal surface.

6. Run the Engraving Job

You will then want to double-check all settings. This way you don't have to spoil any engraving jobs because of something you might have missed. You also want to ensure proper ventilation is around the metal being engraved.

Now it's time to start the engraving process using the laser's control software.

Which Metals Can Be Laser Engraved?

Here's a rundown on some common metals for laser engraving and their pros and cons:

Easy to Engrave:

Aluminum: This is the most popular choice. I love using this metal as I've had the best results with it. Why? It's cheap, lightweight, and engraves cleanly due to the low melting point. The downside is it can be soft and scratch easily. I've noticed sometimes that

Stainless Steel: I've found that this is a tough and durable option. It is great for tags (like dog tags), tools, and even keychains. It creates a nice contrast between the engraved area and the metal. However, some stainless steel alloys might be trickier to engrave.

Other Good Options

Copper and Brass: These engrave well due to their heat conductivity.

Titanium: This strong and lightweight metal is a good choice for high-end items. It creates a sharp, bright white engraving. However, titanium requires a more powerful laser and can be more expensive.

Things to Consider

Coated Metals: Laser engraving can work on anodized aluminum, powder-coated steel, etc. It depends on the coating. The laser can remove it to reveal the metal underneath. Coated metals are my favorite to work with as I currently only have a 20 Watt diode laser.

Difficulty: Generally, metals with high melting points and lower heat absorption are harder to engrave and might require adjustments to the laser settings.

Select the Best Material

This all comes down to the type of engraving you plan on doing and whether or not your machine can handle the job. Below will be a breakdown of the pros and cons of the main types of laser engravers.

Diode Laser

Pros: Affordable, compact size, easy to use, good for basic engraving on some materials.

Cons: Lower power, slower engraving speed, limited material compatibility, not ideal for deep engraving.

CO2 Laser

Pros: More powerful than diode lasers, faster engraving speeds, wider range of materials, good for deeper engraving.

Cons: More expensive than diode lasers, larger size, requires water cooling (in some models), maintenance required.

Fiber Laser

Pros: Most powerful and precise, extremely fast engraving speeds, works on metals and some non-metals, very durable, low maintenance.

Cons: Most expensive option, complex setup, safety precautions due to high power, not ideal for some non-metals (like wood).

Best Laser Engraver for Metal Engraving

The best laser engraver for metal will come down to your requirements. If you will only be engraving on anodized metals, a diode laser will be your best bet as it is cheaper than all the other types of lasers and gets the job done just as good as long as you use it on the correct materials.

If you want to do deep engravings on bare metals, you will want to go with fiber lasers. These lasers are specifically designed to engrave on metals.

Choose the Applications for Which You Want To Use Laser Engraving

CO2 Laser Engravers

- Wood

- Acrylic

- Glass

- Leather

- Fabric

Fiber Laser Engravers

- Metal

- Stainless Steel

- Aluminum

- Anodized Metals

- Titanium

Diode Laser Engravers

- Wood

- Acrylic

- Leather

- Anodized Metals

Which metal produces which colors?

On the left we will have the type of metal and on the right we will have the engraving color.

- Tungsten Carbide (Regular) - Dark Gray, Almost Black

- Tungsten Carbide (White)- Dark Gray, Almost Black

- Tungsten Carbide (Black) - Light Gray/Gold

- Gold Plated Tungsten Carbide - Light Gray/Gold

- Titanium - Mid Gray

- Black Titanium - Dark Gray/Black

- Gold Plated Titanium - Dark Gray/Black

- Black Ceramic- Almost Black

- Platinum - Lighter Shade of Silver

- Silver - Lighter Shade of Silver

- Cobalt - Mid Gray

Proper Safety Precautions Before Engraving

Safety should always be prioritized when using any type of laser engraver. Here's a simple checklist for you to remember:

- Eye Protection: Laser beams can cause damage to your eyes so you will always want to wear eye protection when handling any of these machines.

- Fumes and Dust: Proper ventilation is necessary to remove fumes and dust particles created during engraving. This is especially necessary when working with metal particles.

- Fire Safety: A fire extinguisher should always be readily available in case of any emergencies. Some materials that we all engrave are flammable.

- Electrical Safety: Electrical safety practices should always be followed. Avoid operating the laser with wet hands or near water sources as this can cause a short or damage to you or the machine.

Related Articles

-

How to Laser Engrave Leather | Step-By-Step Guide

Can You Laser Engrave Leather?

How to Laser Engrave White Tiles Painted Black?

What Is The Best Low Cost Laser Engraver? My Opinion

How to Laser Engrave Acrylic with a Diode Laser: A Step-by-Step Guide

My Hands-On Review of the Monport 6-Watt Diode Laser Engraver

Laser Etching Glass

Laser Engraving A Photo | Full Guide

How Much Does Laser Engraving Cost

Is Laser Engraving Hard to Learn?

Why is laser engraving so expensive?

WHAT IS A LASER CUTTING MACHINE?

Top 7 Laser Engraving Business Ideas

10 Essential Safety Precautions for Home Laser Engraving Projects

Laser Engraving Cutting Boards | How To

Where To Buy Laser Cutting Materials?

Laser Engraving QR Codes

What Is DPI In Laser Engraving

How Much Is A Laser Engraving Machine